Tenoning Jig

Tenoning Jig is a wonderful accessory tool that not only makes your work fast and hassle free but also helps you to create very precise smooth cuts, especially for tenons in wood. It simply locks the board upright as you pass it across the saw blade. The locked board doesn’t move at all and the blade can cut the cheeks and shoulders of a tenon very accurately. Cutting a tenon from all the four sides makes it fit perfectly in the joint and also conceals it completely.

Woodford Tooling caters all the demands of woodworkers. Being a leading supplier in UK and overseas, it provides the best quality cutting machines, blades and even accessory tools at special discounted offers that makes wood cutting easy and enjoyable task.

Key Features of Tenoning Jig

- The basic task of Tenoning Jig is to help in cutting smooth tenon that creates strong long lasting glue joints. It can also be used to cut grooves and dadoes out of wood when attached with suitable table saw.

- It usually comes with adjustable angle settings that can be set for cutting straight, angled or mitered tenons. Standard 3/8″ x 3/4″ mitre bar fits most mitre gauge slots including T-slots of this standard size.

- Its heavy cast iron construction provides extra stability which holds wood firmly while cutting tenons.

- It has built in clamps which lock the wood piece during cutting so that it doesn’t move while cutting.

- It comes with extra large handles that make it easily operable. Long handles also take care of your safety while operating the table saw along with Tenoning Jig.

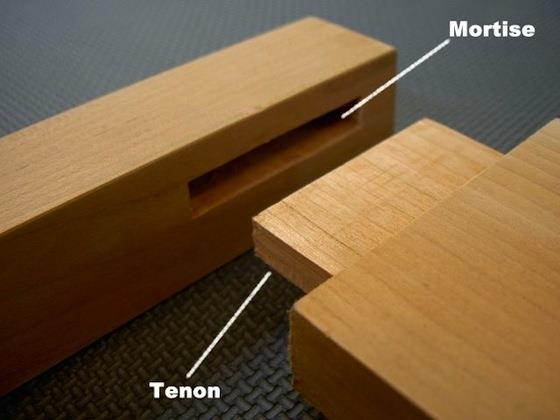

What is a Tenon and Mortise Joint?

Ancient houses in Germany, about 7000 years ago, holds back the history of the oldest preserved wooden frame architecture of the World. These frames were connected to each other by tenon and mortise joint. Then, these joints were used extensively by Romans in wood frame work and stonework. We can call the tenon and mortise joint as the strongest joint that the woodworkers ever make. These types of joints are used to join two pieces of wood placed at 90 degree angle to each other. These joints can be created very easily and are also very long lasting.

How a Tenoning Jig Works?

Setting up Tenoning Jig and using it is quite simple but before setting up Tenoning Jig, you should raise up the table saw blade and make sure that the blade is square to the side table. The blade should also be parallel to miter gauge slot in the table as the Tenoning Jig rides there.

- Attach Tenoning Jig to the Table Saw.

- Place a board or wood piece to be tenoned against the fence on Tenoning Jig and supported by a back support plate that holds the board upright.

- When the board is at the right position you have to lock it down with the help of clamp handle attached to it so that it doesn’t move.

- The fence assembly is attached to a heavy duty cast iron assembly base which slides with the help of bar on the miter gauge slot on the table.

- Make a mark on the board for the tenon.

- A stop piece keeps the board square in both directions.

- Turn the fine adjustment knob attached to Tenoning Jig in order to line up the marks on the board with the teeth of the blade.

- Lock down the jig with the handle attaches to it and set the height of the blade for the tenon.

You can also put some paste wax on the table saw table and on the bottom of this jig. This will ensure that the jig will slide smoothly over the miter gauge.

Now, your Tenoning Jig is ready to be used for cutting tenons. You can cut as many tenons as you like. It always ensures your safety and provides you with the smoothest tenons when used along with the blade.

So, a Tenon Jig is just not an accessory but a must have tool for your workshop. Hurry up and avail the lowest price offer..buy online now!!