Tips and tricks are always seen as blessings as these save your precious time, energy and make your life easier. Tips from experienced woodworkers help in managing and doing complex tasks with ease. We have collected few tips from wise woodworkers about their tools and how to deal with certain problems. Let’s have a look…

10 Tips on woodworking tools

- General Safety Tips for woodworking tools: Before operating on power based woodworking tools, read the instruction manual very carefully. Knowing your machine well before using it is a must. Take proper training and never ignore safety practices. Always wear safety glasses or goggles, or a face shield (with safety glasses or goggles). Also, protect your hands and feet with suitable gloves and shoes. However, do not wear gloves when you are working too close to rotating blades and other machinery parts where it can tangle in between the blade.

2. Switch OFF the power button and unplug the power cord before actually examining, cleaning, repairing or changing a blade or any tool part as it saves you from accidental hazard. The habit of turning off unnecessary power when it is not required will also save your hard earned money.

3. Check stock for foreign objects: Always check the wood piece or stock for foreign objects like nails, screws, staples or any metal part entangled within it and remove it first before feeding to the blade of machine. This step is particularly necessary if you are using scrap wood. These can become a dangerous projectile if it comes in contact with a spinning blade and can damage the blade also.

4. Do regular maintenance of your woodworking tools: Keep your tools always sharp for smooth and professional results. Worn out or dull tools like blades, chisels, planes, scrapers and gouges don’t cut evenly and could chip out wood. Sharp blades increase your efficiency, make your work easier and give you cleaner cuts.

5. Use a push stick: Jigs like push stick protect your fingers from being fed into the blade of the machine accidently. Always use a push stick to push a wood piece that is less than 6 inches (152.4mm) through the blade. Proper and durable push sticks can be built in the shop or purchased from any fine woodworking supplier.

While the machine is still operating, do not remove sawdust or cuttings by hands from the cutter head of the machine. Use a push stick or brush when the machine has stopped running. Do not use compressed air to remove sawdust, turnings, etc. from the cutter head of the

6. Say NO to free hand cut on a table saw: Never try to attempt a free hand cut when you are working on a table saw. Use a push stick, the fence or the miter gauge to feed the wood piece to the blade. Use one of these options and always try to cut or rip along the direction of the grain of wood piece.

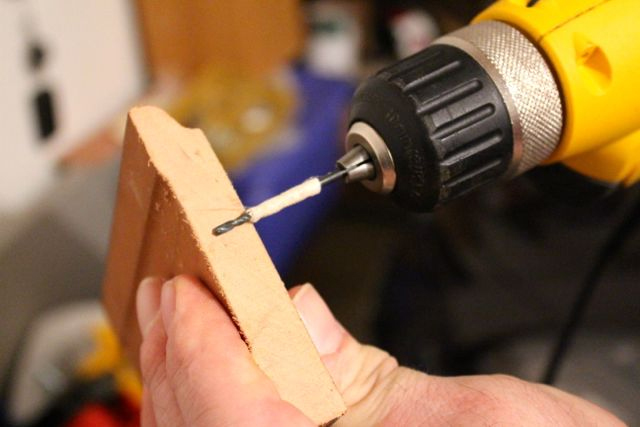

7. Setting the depth of the handheld drill: Simply, roll up some tape on the drill bit to the point where you want the drill to stop as all holes do not require to be drilled thoroughly. Setting up stops on a drill press is quiet easy but sometimes using the drill press isn’t the best option.

8. Belt sander stop block: If you

are using belt sander for sanding your boards, make a stop block of same

thickness and clamp it in order to stop the board from jumping away

from the work bench.

9. Magnetize your screwdriver: A magnetized screwdriver could save lots of dropping screws and searching time. This old trick is done by rubbing magnet along the shaft of a screwdriver many times in one direction only. You could also attach a magnetic strip on the wall and hang small tools and iron parts so that these are not misplaced.

10. Recharge station for your cordless power tools: Cordless tools are great to work with as they can reach anywhere but recharging chargers and their tangled cords could mess up your workspace. It is a good to organise all your chargers at one spot and plugging then in one power strip.

No comments:

Post a Comment